Development of Basic Safety Design Aid Tools

for Robot Nursing Devices

The intrinsic safety design support tool was developed with the aim of helping the intrinsic safety design, with a particular focus on the development of robotic nursing care equipment. When developing equipment, it is necessary to first carry out a risk assessment and then apply protection measures in the order of intrinsic safety design / safety protection / usage information to reduce risk, but we are entering a new field of robot nursing equipment. This is because the developer who wants to do so needs a clue as to what kind of risk is expected and how to proceed with the intrinsically safe design.

The intrinsic safety design support tool was developed with the aim of helping the intrinsic safety design, with a particular focus on the development of robotic nursing care equipment. When developing equipment, it is necessary to first carry out a risk assessment and then apply protection measures in the order of intrinsic safety design / safety protection / usage information to reduce risk, but we are entering a new field of robot nursing equipment. This is because the developer who wants to do so needs a clue as to what kind of risk is expected and how to proceed with the intrinsically safe design.

The intrinsically safe design support tool has the following basic functions.

(1) Functions related to the implementation of risk assessment: Implementation and recording of risk assessment, viewing of recorded risk assessment results, printing of risk assessment results

(2) Data editing functions: Add / edit / delete data, create / delete relationships between data

(3) Data management functions: account management, data import / export, database backup

(4) Editing the basic specifications of the target robot nursing care equipment

Using the essential safety design support tool, carry out risk assessment according to the following procedure.

I) Determining the basic specifications of the target robot nursing care equipment and determining the restrictions on machinery

Ii) Selection of risk estimation method

Iii) Setting risk assessment criteria

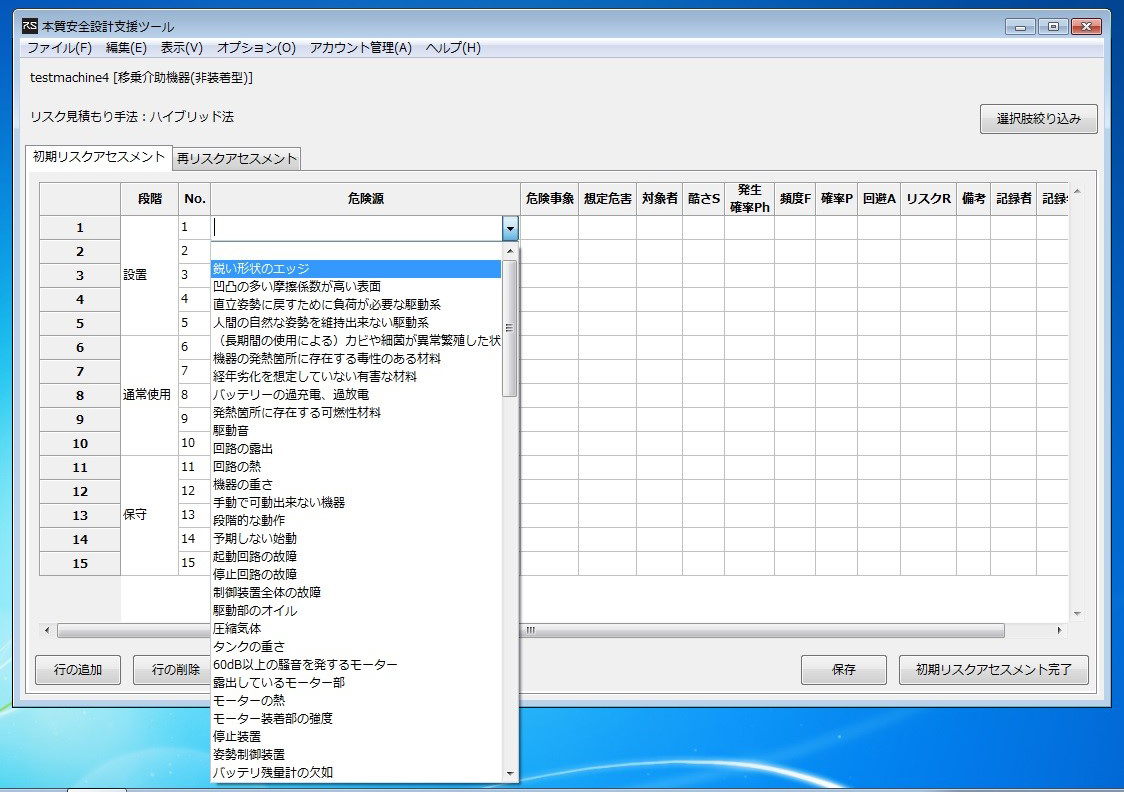

Iv) Identification of hazard (Fig. 1)

V) Identification of dangerous conditions and assumption of dangerous events

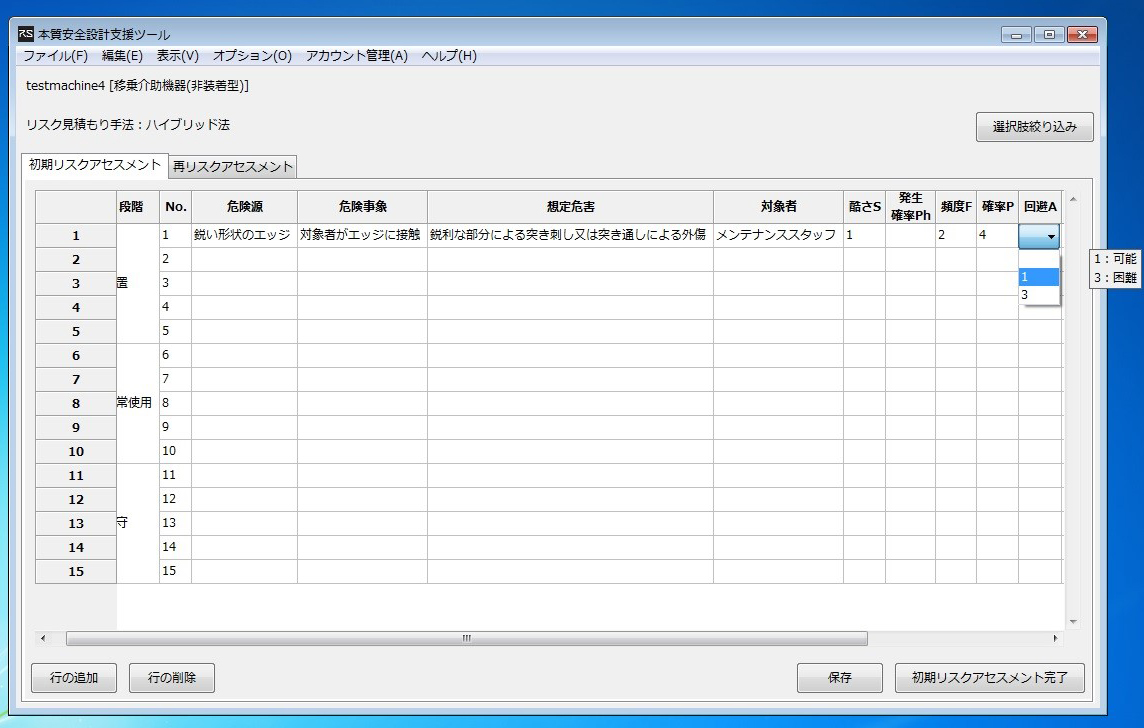

Vi) Risk estimation (Fig. 2)

Vii) Risk assessment

Viii) Examination of protection measures (Fig. 3)

Ix) Re-risk assessment (risk estimation, risk assessment, handling of residual risk)